News And Events

Type of wire reinforced hydraulic hose

Hydraulic hoses can be used to drill through rocks, move earth, lift heavy objects, and perform other complex operations. They can also transport fluids under high pressure. The right type of reinforcement material is essential to ensure that the hose performs according to its intended use. Hydrauli

Read More

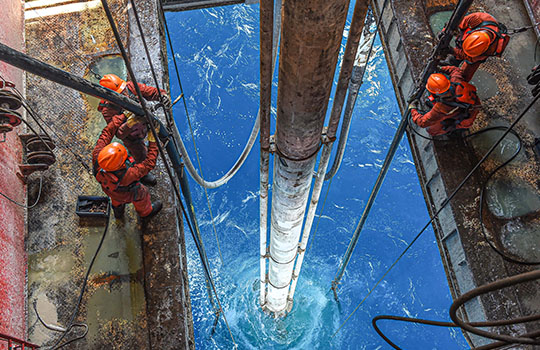

Proper maintenance of large diameter oil hose

Choosing the right hose for the job is essential to increase uptime and safety. The wrong choice can lead to unnecessary downtime, higher costs, and higher risks. Maintenance technicians and plant managers must consider the material, construction type, end connectors, and application of the hose. Th

Read More

Application range of super wear-resistant industrial hose

Application of super wear-resistant industrial hose series: industrial wear-resistant hose series can be heat resistant, wear-resistant, weather resistant. Its high strength textile reinforcement material makes it ideal for harsh industrial environments. It can be used for conveying liquids, powders

Read More